Environmental Management

Water

The pulping processes requires reasonable quantities of freshwater to move the pulp fibres through the various stages.

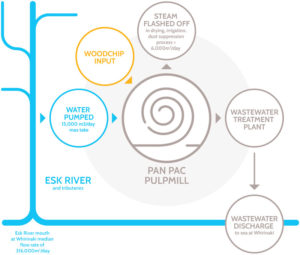

Figure 1 is a simplified schematic of total water intake to the Pan Pac Pulp operations. Our Sawmill’s usage of freshwater is minor in comparison to the requirements of our Pulpmill operations.

Pan Pac holds a current consent from the Hawke’s Bay Regional Council to take up to 15,000 m3 of water per day for use on the Whirinaki site. Potable water and water supply for staff facilities is supplied via the Hastings District Council’s reticulated water network.

In 2020, Pan Pac upgraded its water intake by installing screens in the bed of the Esk River. The water intake screens are located 1.5m below the gravel bed of the Esk River and they significantly reduce the amount of sediment extracted. This reduces the cost of water treatment onsite and is also good news for small fish and eels as the screens protect them from entering the water intake system.

Wastewater Irrigation

Our wastewater from staff facilities is treated on site and recycled for irrigation within the forest at the back of the Whirinaki mill site. The irrigated of wastewater utilises the nutrients to promote tree growth and ensures that the discharge does not affect water quality in nearby streams and waterways.

Process Wastewater

In 2012, Pan Pac invested $20m to install a state-of-the-art Wastewater Treatment Plant (WWTP) that biologically treats wastewater produced in our Pulpmill. Our WWTP is especially designed to remove the organic compounds in wastewater generated from the pulping process. If we didn’t do this, the wastewater would have an adverse effect on the marine environment in which it is discharged.

To read more about our Wastewater Treatment Plant, click here.

Solid Waste

Where possible, solid waste generated on site is utilised for energy generation. Solid waste including bark, sawdust, shavings from the planer mill, and effluent solids, is burned in the site boilers providing energy for drying lumber and wood pulp.

As a result, we reduce the amount of solid waste we send to the site landfill.

We offer a community waste diversion programme that currently diverts approximately 30,000 tonnes per year of wood waste from landfill. The waste material is chipped and used in Pan Pac’s boilers for energy generation.

Other

Noise

We know that keeping our noise levels at a minimum is important to the community that we are part of. That’s why we proactively work to minimise the noise we make. The Whirinaki site is located within Hastings District Council’s Whirinaki Industrial Zone. The zone has four noise measurement stations for checking compliance against the Hastings District Plan. We work with acoustic experts to ensure that expansion and development on site doesn’t compromise the management of noise coming from the site. We actively use technology to support noise management and we have purchased noise monitoring equipment to help identify problematic noise sources.

Air Quality

We closely monitor emissions to air from site operations. Air quality in New Zealand is regulated by the National Environmental Standard – Air Quality (NESAQ) and implemented by the Hawke’s Bay Regional Council. Our air discharge consent requires PM10 levels to be constantly monitored on site and any exceedances of the NESAQ standards must be reported to Council. Pan Pac has invested in advanced air quality monitoring equipment to continuously monitor both PM10 and PM2.5 at various locations across the Whirinaki site.

Forests and the Environment

Our forests offer a range of ecosystem services and are home to an abundance of native flora, fauna and archaeological sites. The protection of these taonga is important for the community and Pan Pac takes the management of these areas seriously. Pan Pac managed forests comprise some 4,782 hectares of native reserves and 76 archaeological sites. Forests are important tools for managing the effects of climate change and Pan Pac’s forests convert approximately 1,272,640 tonnes of Co2 per year.

Green House Gas Emissions and Energy

Our greenhouse gas emissions are minimised by reducing the combustion of natural gas and fossil fuels. We generate energy from wood waste using two onsite boilers to generate steam energy, and by substitution of purchased electrical energy using the site’s steam powered turbine. Heat energy produced by the site boilers reduces the need to burn fossil fuels to provide heat for drying lumber and wood pulp.

Toitu logo and info re Enviromark programme and carbon footprint to go here. [please add this in as placeholder]

Content to go here. Content to go here. Content to go here. Content to go here. Content to go here. Content to go here. Content to go here. Content to go here. Content to go here. Content to go here. Content to go here. Content to go here. Content to go here. Content to go here. Content to go here.